Industrial Component Bags – Built for Strength and Precision

When it comes to packaging industrial parts, one standard matters above all: protection.

VeloRaft Plast designs and manufactures Industrial Component Bags specifically for sectors that demand exceptional durability, chemical resistance, and reliability in every shipment.

Crafted from high-density polyethylene (HDPE) or medium-density polyethylene (MDPE), these bags are built to withstand mechanical stress, rough handling, and environmental exposure — ensuring your products reach their destination safely and in perfect condition.

Designed for Industrial Performance

Each VeloRaft Industrial Component Bag is produced using multi-layer extrusion and reinforced sealing technology to deliver superior strength.

These bags are resistant to tearing, punctures, and moisture — essential features when packaging heavy or sharp-edged components.

The smooth surface allows for easy labeling and barcode application, while the anti-slip matte option prevents shifting during transport.

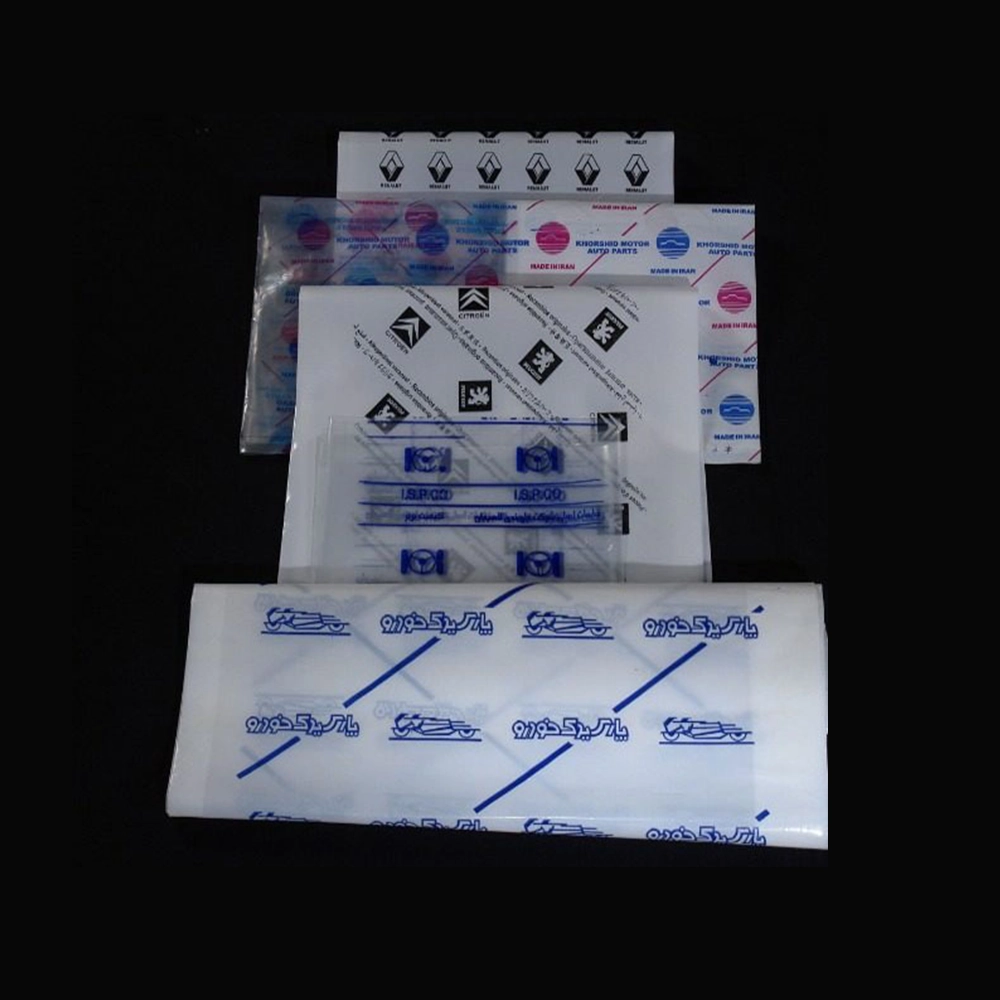

They can be supplied in transparent, semi-opaque, or colored finishes, depending on your storage and identification needs.

This makes them suitable for both automated packaging lines and manual operations in factories or warehouses.

Protection Against Harsh Conditions

Industrial environments often expose packaging to heat, dust, and oil — conditions that ordinary plastic bags can’t handle.

That’s why VeloRaft’s Industrial Component Bags are enhanced with anti-static, anti-oil, and UV-resistant additives, ensuring optimal performance even in challenging logistics or outdoor storage.

Their superior sealing capability keeps contents safe from contamination, corrosion, and humidity — a crucial advantage for metal or electronic parts.

For export clients, these features guarantee compliance with international shipping and safety standards, including REACH and RoHS directives.

Custom-Made for Every Application

No two industries are the same — and neither are their packaging needs.

VeloRaft Plast offers full customization for its industrial bags, including:

- Custom sizing and thickness (typically 50 to 200 microns)

- Branding and printed technical information

- Zipper or valve-sealed versions for specific products

- Special formulations for anti-corrosion or VCI protection

Whether you’re exporting machinery, assembling electronic boards, or packaging mechanical spares, VeloRaft provides a tailored solution that protects your product and strengthens your supply chain efficiency.

Sustainability and Compliance

VeloRaft’s industrial component bags are made from recyclable materials and produced under strict ISO 9001 quality and environmental standards.

The production process minimizes waste and energy consumption, ensuring a lower carbon footprint for all clients.

Eco-friendly or partially recycled options are available for customers pursuing sustainable packaging goals.

Applications

- Automotive Industry: Packaging of metal, rubber, and plastic car parts.

- Electronics & Electrical: Anti-static protection for circuit boards, tools, and components.

- Machinery & Tools: Safe transport of heavy-duty industrial parts.

- Export Logistics: Long-term storage and moisture-resistant packaging for global shipment.

Key Advantages

✅ Made from high-strength HDPE/MDPE

✅ Anti-tear, moisture-resistant, and oil-resistant

✅ Customizable size, color, and thickness

✅ Printable for branding or part labeling

✅ Compliant with export and industrial standards

Conclusion

VeloRaft Industrial Component Bags represent the foundation of reliable industrial packaging.

They’re engineered to protect high-value components from the hazards of transit, storage, and handling — ensuring quality from factory to final destination.

Built with precision and crafted for resilience, these bags reflect VeloRaft’s commitment to industrial innovation and global reliability.

Because in every shipment, protection isn’t optional — it’s guaranteed.