Factory Packaging Bags – Industrial Strength for Global Standards

For manufacturing and export industries, packaging must go beyond protection — it must guarantee reliability.

That’s why VeloRaft Plast produces Factory Packaging Bags engineered to handle the toughest industrial and logistic conditions.

Made from high-density polyethylene (HDPE) or medium-density polyethylene (MDPE), these bags are designed to ensure maximum resistance against tearing, punctures, and environmental stress.

Whether for domestic manufacturing or international shipment, VeloRaft’s factory bags provide unmatched performance and long-term reliability.

Built for Heavy-Duty Performance

Every Factory Packaging Bag is manufactured with thick, multi-layer film structures for extra durability and sealing integrity.

These bags can handle large volumes and high loads, making them suitable for packaging raw materials, semi-finished products, and export-ready goods.

The smooth, anti-slip surface makes stacking and handling easier, while the reinforced bottom seals prevent rupture under heavy pressure.

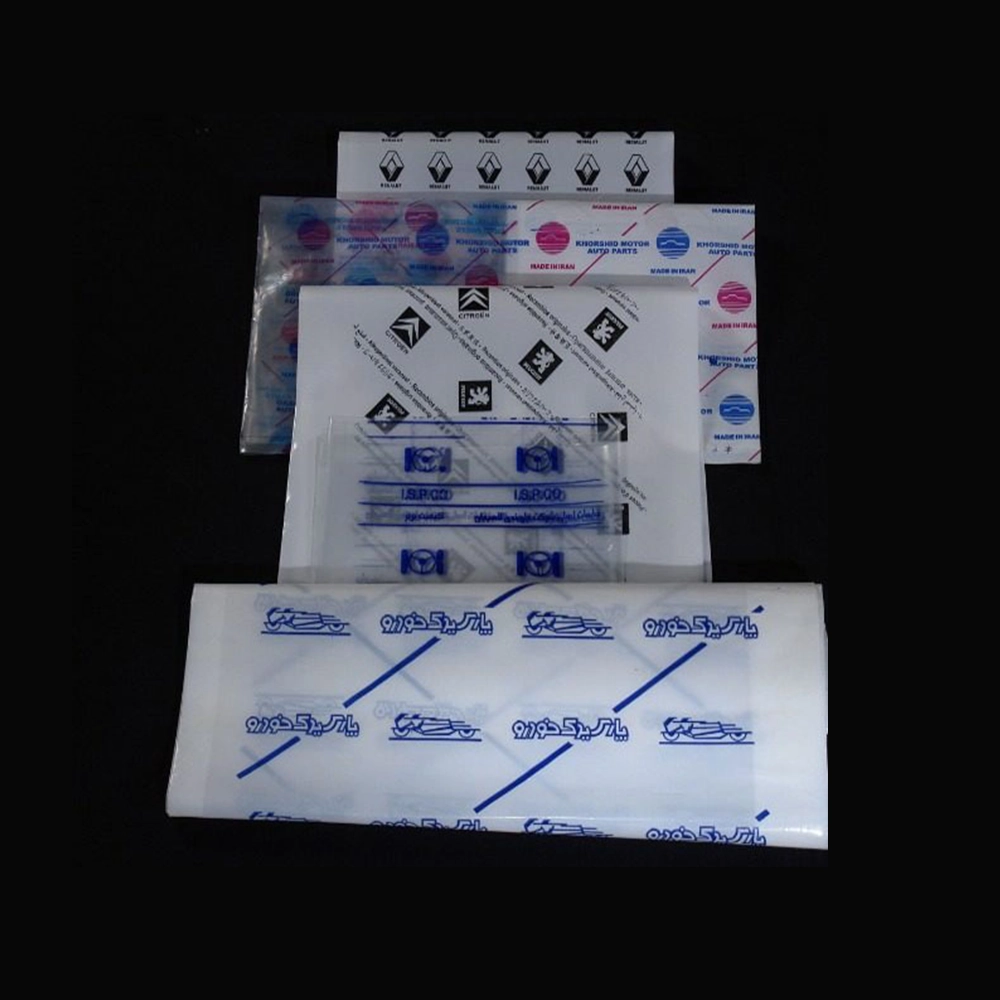

Available in both transparent and colored finishes, these bags can also be printed with brand logos, technical data, or safety instructions as per customer needs.

Designed for Industrial and Export Operations

VeloRaft’s Factory Packaging Bags are ideal for industries that require long-term storage or overseas shipping.

They protect goods from dust, moisture, and UV exposure during transport, ensuring product integrity even in challenging conditions.

These bags are used across a variety of sectors including chemicals, automotive parts, fertilizers, textiles, and electronics — all requiring strong, safe, and consistent packaging.

For exporters, the bags comply with ISO 9001 and REACH standards, ensuring global acceptance and logistic efficiency.

Customization That Fits Every Operation

Because every production line is different, VeloRaft Plast offers full customization for its factory packaging bags:

- Adjustable thickness (60–250 microns) based on load requirements

- Variable dimensions for pallets, drums, or cartons

- Multi-color printing for brand visibility and labeling

- Optional vent holes, anti-static film, or UV-stabilized versions

This flexibility allows manufacturers and exporters to integrate VeloRaft packaging seamlessly into their existing systems.

Sustainability in Every Layer

Even in industrial packaging, sustainability matters.

That’s why VeloRaft uses recyclable polyethylene resins and maintains eco-efficient production methods to minimize waste.

Upon request, these bags can also be made from partially recycled materials or oxo-degradable formulations, aligning with modern environmental requirements for global logistics.

Each bag is manufactured under a strict quality control system that ensures uniformity, strength, and clean appearance — hallmarks of the VeloRaft Plast brand.

Applications

- Manufacturing Plants: Packaging of parts, semi-finished goods, and raw materials

- Warehousing & Logistics: Storage and transport of industrial products

- Export & Shipping: Moisture-proof packaging for international distribution

- Construction & Agriculture: Heavy-duty containment for bulk materials

Key Advantages

✅ Made from industrial-grade HDPE/MDPE film

✅ High mechanical strength and sealing performance

✅ Customizable size, color, and printing options

✅ Compliant with export and ISO standards

✅ Recyclable and eco-conscious manufacturing

Conclusion

VeloRaft Factory Packaging Bags are built to perform where strength and reliability are non-negotiable.

Engineered for manufacturing and export operations, they provide the durability industries rely on — from the assembly line to the global marketplace.

For businesses that demand industrial-grade protection with a professional finish, VeloRaft Plast delivers one clear solution:

Tough packaging, trusted worldwide.